Technical information

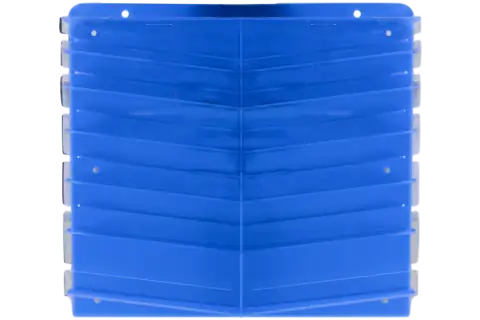

MOUNTED FLAP WHEEL display

- PFERD TOOLS type

- FAN GRINDER DISPLAY (DISPLAY ONLY) PAUS

- Packaging unit

- 1 piece

Description

Special features

Recommendations for use

Safety notes

PFERD TOOLS VALUE