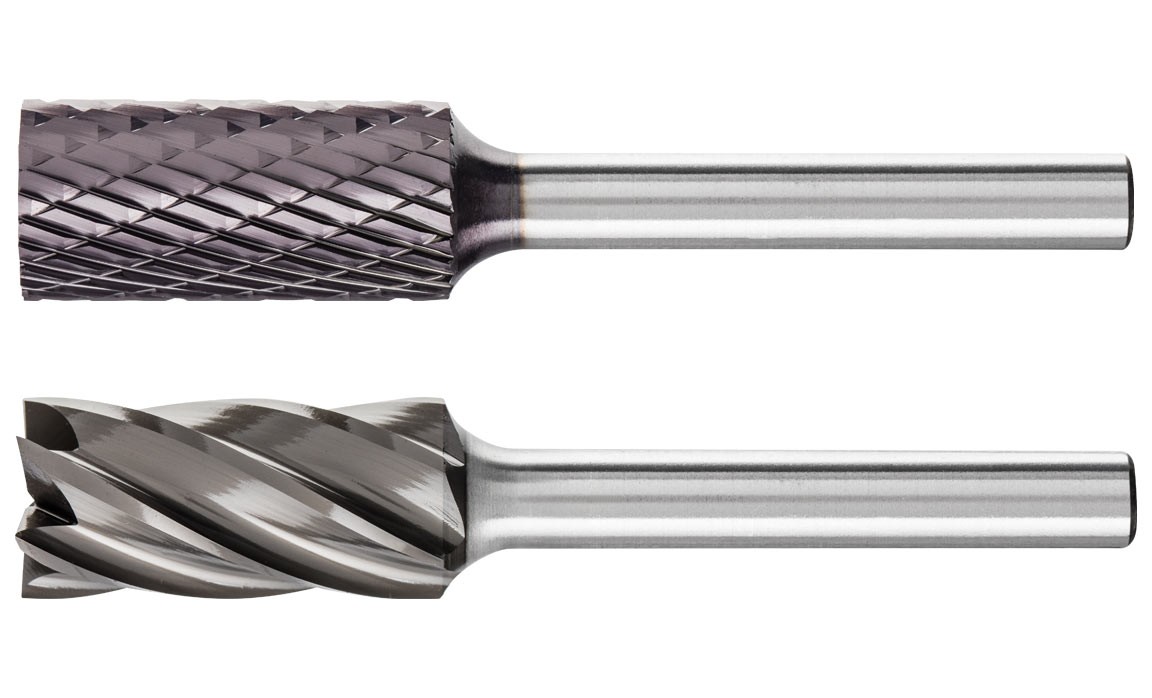

Tungsten carbide burrs with HICOAT coatings

PFERD offers tungsten carbide burrs with HICOAT coatings to tackle particularly demanding applications. The anti-wear coatings enable effective chip removal thanks to the improved anti-adhesion characteristics and increase the tools' service life.

Two different coatings are available.

The HICOAT coating HC-FEP is specifically designed for iron and steel materials.

The HICOAT coating HC-NFE is mainly used for long-chipping and lubricating aluminium alloys and non-ferrous metals.

In general, all PFERD tungsten carbide burrs are also available with HICOAT coatings.

Advantages:

- Improved anti-adhesion characteristics.

- Effective chip discharge.

- Lower thermal loads.

- Increased service life.

- Also suitable for use at higher cutting speeds when compared with uncoated burrs.

HICOAT coating HC-FEP for iron and steel materials

- High hardness and wear resistance.

- Effective chip removal through improved anti-adhesion characteristics.

- Very high resistance against thermal load.

- Increased service life.

- Also suitable for use at higher cutting speeds when compared with uncoated burrs.

ALU cut with HICOAT coating HC-NFE

The use of burrs with the PFERD HICOAT coating HC-NFE prevents chips adhering during work on soft aluminium alloys. This increases the tool life and improves the surface quality of the workpiece.

- Mainly used for long-chipping and lubricating non-ferrous metals.

- Highest stock removal rate.

- Effective chip removal through improved anti-adhesion characteristics.

- Lower thermal loads.

- Longer service life.