COMBIDISC abrasive discs CD/CDR RS

COMBIDISC ceramic oxide grain mini fibre disc CDFR dia. 75 mm CO-COOL120 for backward grinding

CDFR 75 CO-COOL 120 RS

Matching accessories & spare parts

Technical information

COMBIDISC ceramic oxide grain mini fibre disc CDFR dia. 75 mm CO-COOL120 for backward grinding

- Abrasive

- RS ceramic oxide grain CO-COOL version

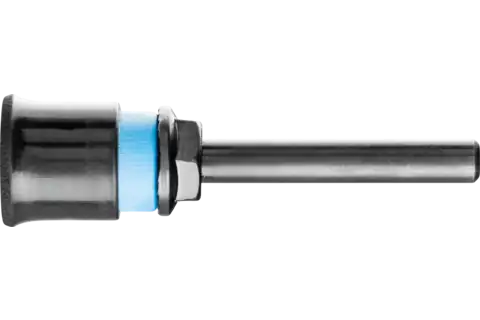

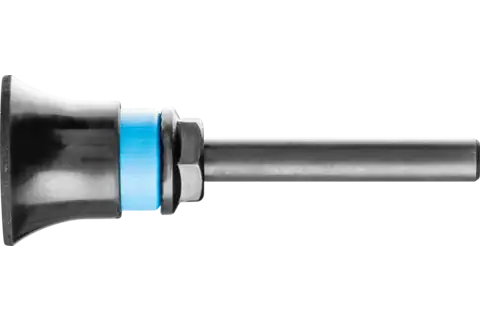

- Clamping system

- CDR system

- Dia. external

- 75 mm

- Grit size

- 120

- RPM, optimum

- 2500 - 9000 RPM

- Packaging unit

- 50 pieces

Description

Special features

Recommendations for use

Ordering notes

Safety notes

- Materials that can be worked

- Applications

- Drive types

PFERD TOOLS VALUE

PFERD TOOLS EFFICIENCY

recommends COMBIDISC tools to reduce tool changing and setting-up time.

PFERD TOOLS ERGONOMICS

recommends COMBIDISC as an innovative tool solution to sustainably reduce the vibration, noise and dust produced during use and to improve comfort when working.